|

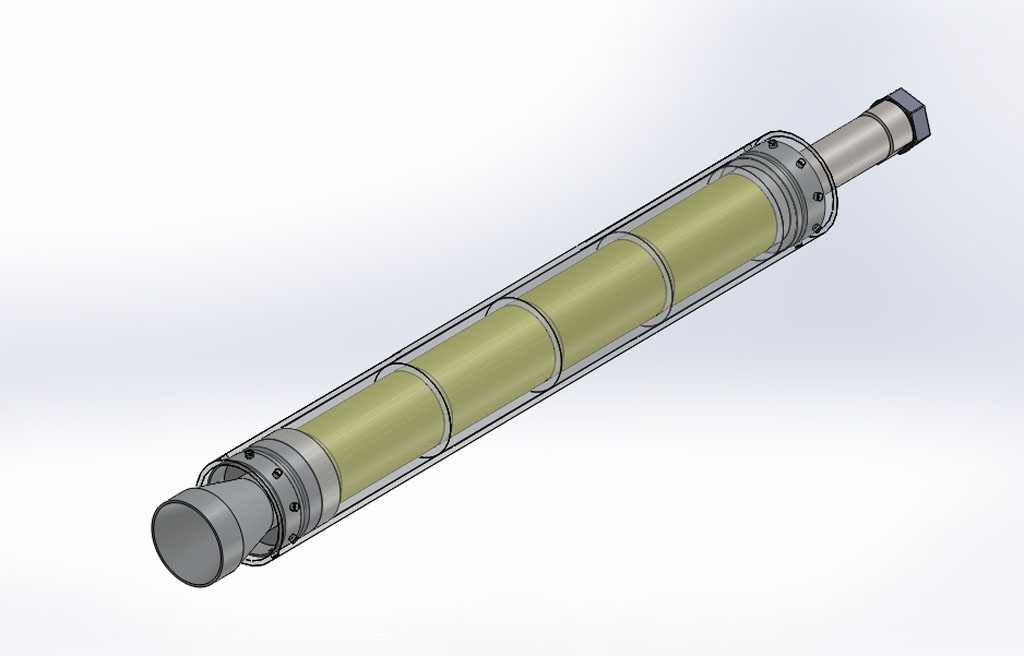

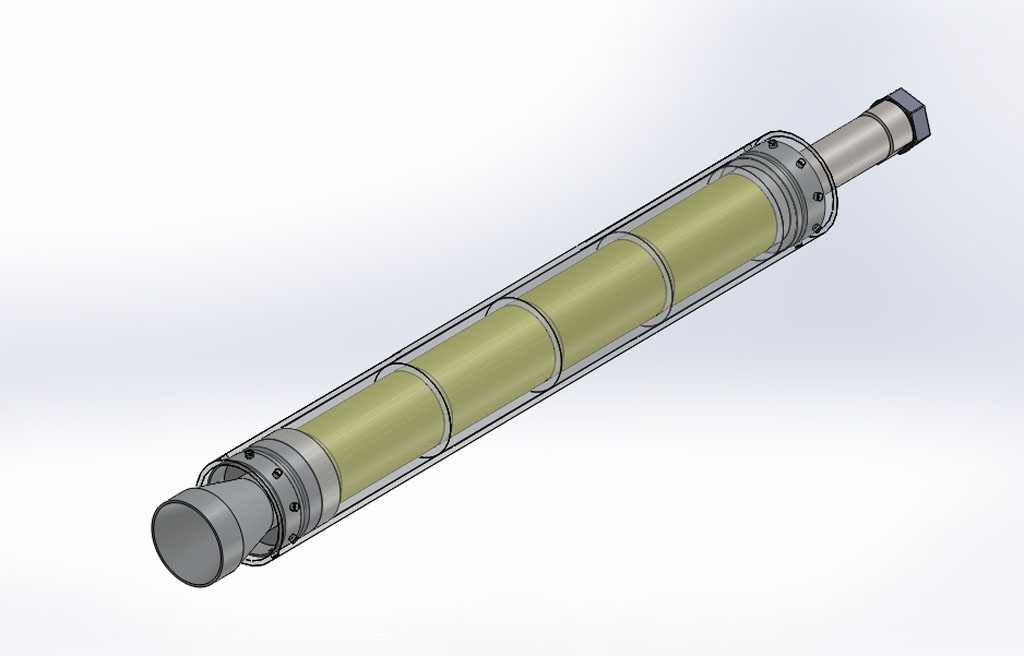

Motor 3D model.

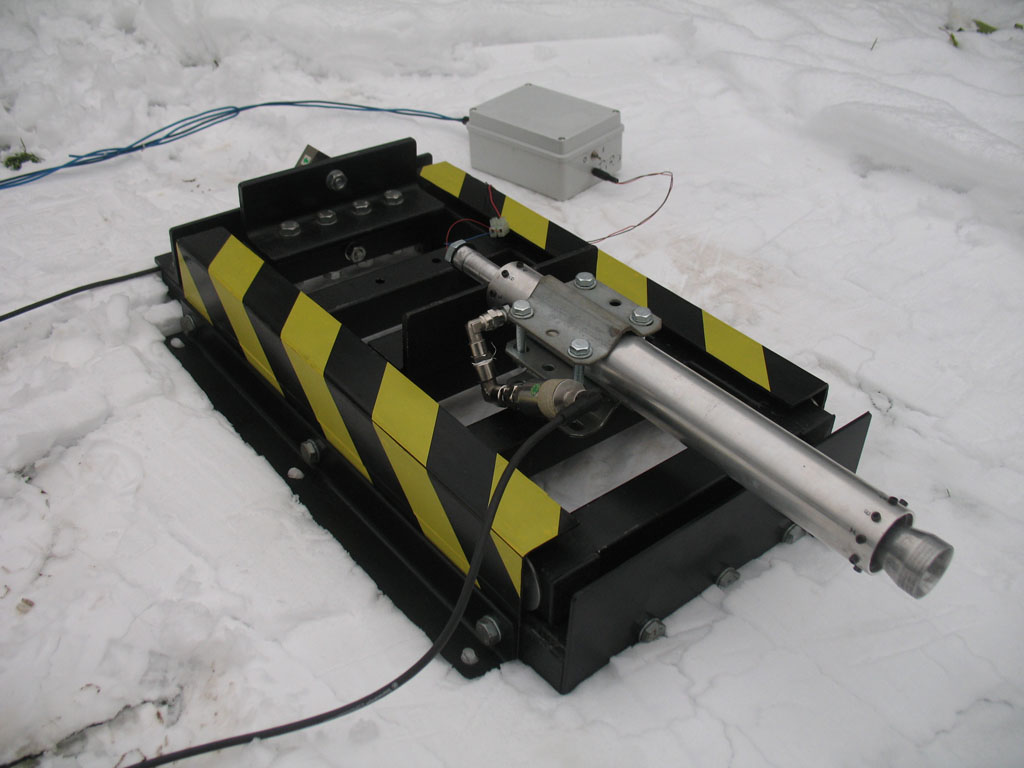

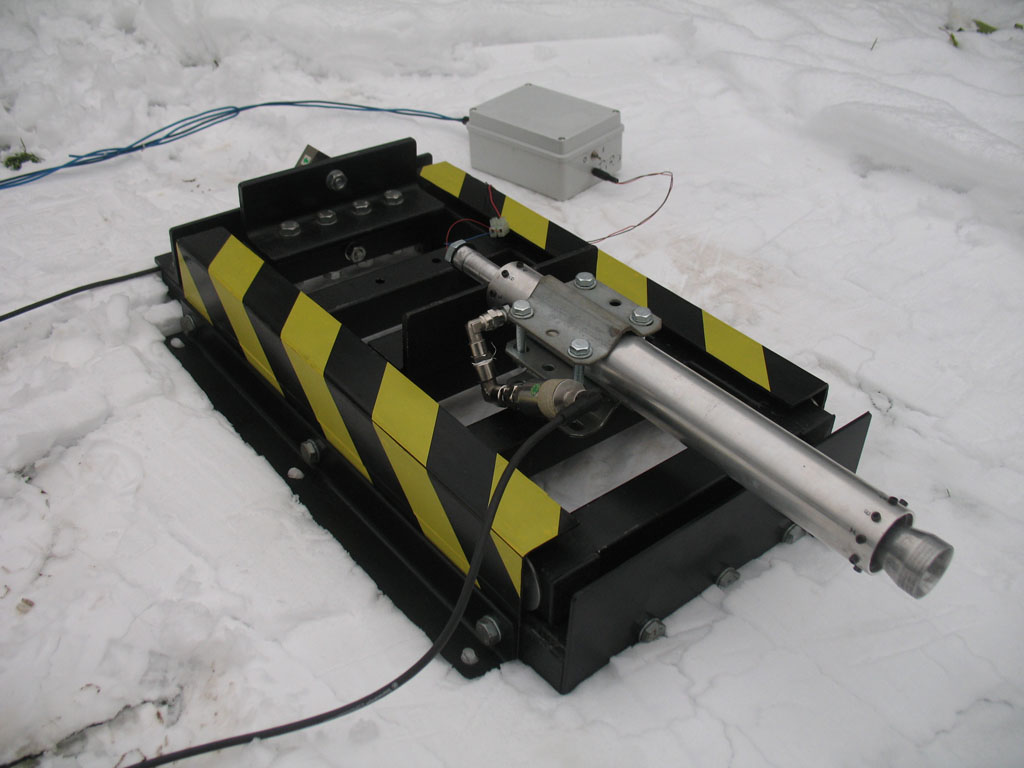

Motor on test stand.

|

PR-V6 is the first motor designed to fly. Hence, gross mass was further reduced and the safety coefficient was lowered to k=2. The material adopted for the case is aluminium 6060 instead of steel, yielding a total dry mass of approximately 580 [g]. A 4 grain configuration was selected, where each grain has a mass of 100 [g].

The liner's thickness was sized according to thermal simulations. The predicted temperature was 68°C on the case. After the first test, we measured the temperature in the hottest and coldest points near the throat and on the bulkhead: their temperatures were 105°C and 50°C respectively. We didn't probe the temperature on the case wall because thermal contact was not reliable enough.

The theoretical optimal chamber pressure is about 70 [bar] for a rocket dry mass of approximately 2.7 [kg], so we chose this value.

A test stand variant (totally similar to the flight one) was purposely built to be fitted with a pressure sensor that, coupled with the load cell, makes the direct measurements of thrust coefficient (CF) possible.

|