|

|

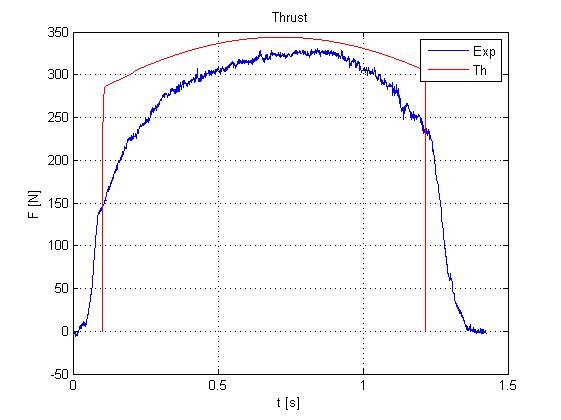

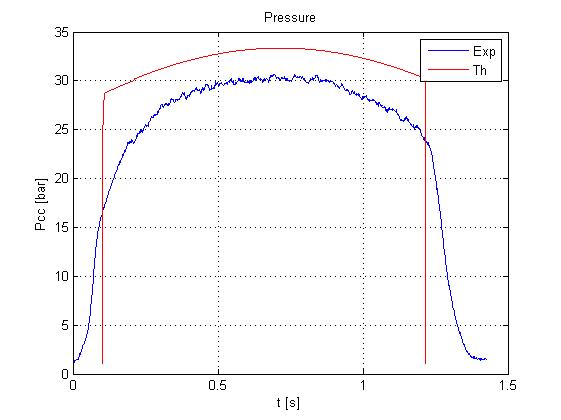

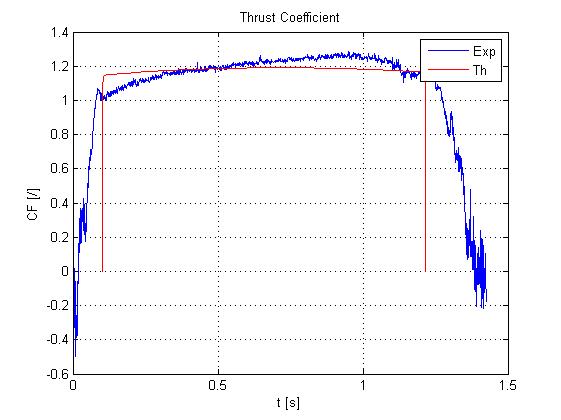

Full load test with four grains processed through H2O mixing and subsequent evaporation. This procedure reduces casting time and increase fuel-oxidant mixing.

We had some trouble with the ignition system. Three more igniters have been made. Moreover, ignition batteries have been discharged during ground test procedures. Eventually the motor started after four hours of work. Pressure and thrust levels as predicted

by corrected theoretical model.

|

Photo

Acquisition frequency [Hz]: 2000

Channel: 2

Load cell offset [N]: +4.79

0 voltage Red PS [V]: 2.074

0 voltage Green PS [V]: /

Propellant: P-1

Propellant mass [g]: 315.3

Mean density [g/cm^3]: 1.907

Ideal density ratio: 99.0 %

Grain number: 4

Spacing (between grains) [mm]: 5

Total grain length (without spacing) [mm]: 243.1

Port grain diameter [mm]: 16.32

External grain diameter [mm]: 33.65

Throat diameter [mm]: 10.5

Expansion Ratio Ae/At [/]: 10.5

Inhibition: External

Action time (ta) [s]: 1.375

Maximum thrust [N]: 333.4

Mean thrust (tb)[N]: 251

Mean pressure (tb)[bar]: 24.4

Total impulse [Ns]: 345.1

Specific impulse [s]: 110.0

Combustion efficiency [%]: 93.7

Nozzle efficiency [%]: 82.7

Pyrogen:

Propellant: P-1

Grain mass [g]: 4.8

Grain length [mm]: 29

Port Diameter [mm]: 3

External Diameter [mm]: 11.6

Motor total mass before burn [g]: 1091

Motor total mass after burn [g]: 785

Non-burned mass [%]: 4.4

Environmental data:

Atmospheric pressure [mbar]: 1027

Air temperature [°C]: 9

|

|

|