|

|

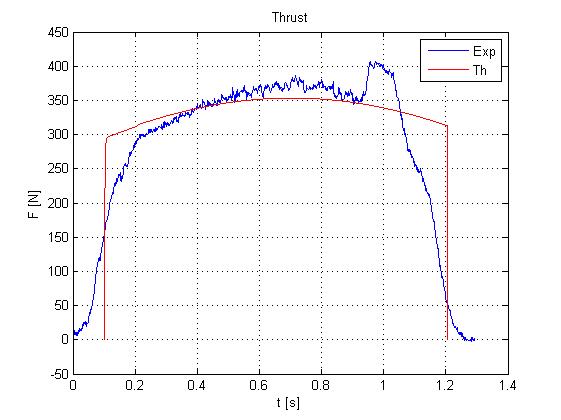

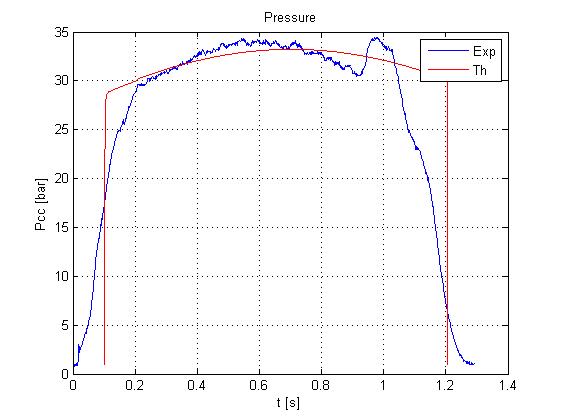

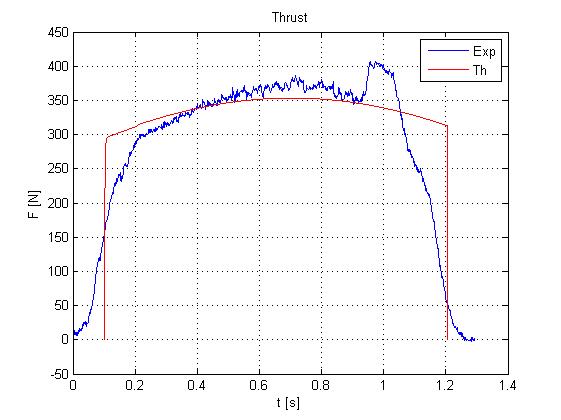

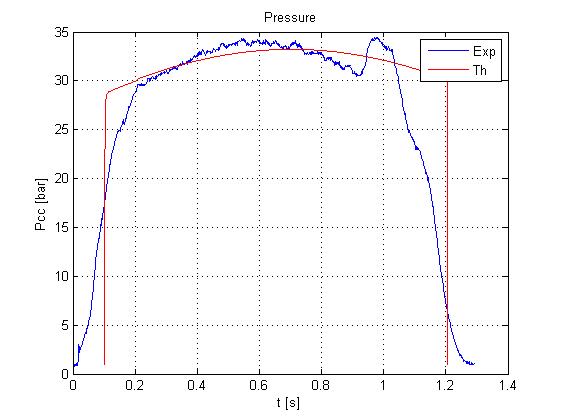

This test was carried with a fully loaded combustion chamber with 4 grains. We measured both pressure and thrust so we can determine the thrust coefficient (CF) directly. In post-processing the code was modified to take in input a 3 column vector with load cell data and possibly two pressure sensors. Only one was fitted. So calculations of CF are made in three ways: one is from pressure data (green curve), one from thrust (red) and the last from both (blue). This one is the real CF of the motor.

However, also in this test, chamber pressure is too low in respect to theoretical calculations. In the next tests we will try to understand why.

|

Photo

Acquisition frequency [Hz]: 2000

Channel: 2

Load cell offset [N]: +3.5

0 voltage Red PS [V]: 2.1016

0 voltage Green PS [V]: /

Propellant: P-1

Propellant mass [g]: 305.6

Mean density [g/cm^3]: 1.898

Ideal density ratio: 98.6 %

Grain number: 4

Spacing (between grains) [mm]: 5

Total grain length (without spacing) [mm]: 242.8

Port grain diameter [mm]: 16.2

External grain diameter [mm]: 33.70

Throat diameter [mm]: 10.5

Expansion Ratio Ae/At [/]: 10.5

Inhibition: External.

Action time (ta) [s]: 1.256

Burn time (tb)[s]: =ta

Maximum thrust [N]: 403.4

Mean thrust (tb)[N]: 286.5

Mean pressure (tb)[bar]: 26.15

Total impulse [Ns]: 359.9

Specific impulse [s]: 118.1

Combustion Efficiency [%]: 98.0

Nozzle Efficiency [%]: 83.4

Pyrogen:

Propellant: P-1

Grain mass [g]: 5

Grain length [mm]: 30.9

Port Diameter [mm]: 3

External Diameter [mm]: 11.5

Motor total mass before burn [g]: 1105

Motot total mass after burn [g]: 789

DIfference between before/after [g]: 316

Environmental data:

Atmospheric pressure [mbar]: 1008

Air temperature [°C]: 8

|

|

|