Sagitta Design

The design phase is the first step into technical aspects of the projects. Most subsystems follow a path that starts from an idea of how to solve a problem and arrives to the final solution; usually the path isn't straight but iterative instead. This project approach also involves a test phase, if the technology is not tested yet.

Let's focus on the various steps:

1) Requirements of the subsystem: we have to find what the subsystem must do and "how well". For example: we want recover the Sagitta rocket system, we need a recovery subsystem. This subsystem can be whatever comes in your mind, as long as it saves the rocket.

2) Preliminary design: in this phase the subsystem is analyzed with mathematical models or with quick real world tests. At this step the first mass budget is outlined.

3) Final design: most critical parts are analyzed through FEM or CFD for mass minimization.

4) Testing: construction of a mockup to test the effective feasibility of the subsystem. Moreover structural load are applied to simulate stresses during operational phase but in safe conditions. This step is required if the technology is new. At this stage a precise mass budget can be calculated.

5) Iterating: after tests on a mockup it is possible to get back at step 2) or 3): this is caused by underestimations or errors.

After these steps the construction of the final subsystem is eventually possible.

Fins Design and Verification

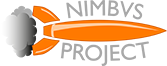

Alpha. |

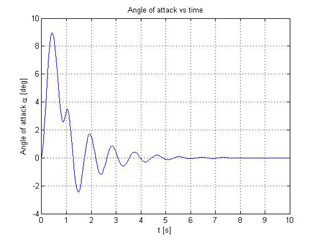

CL vs Alpha. |

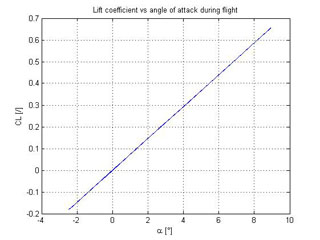

Pitch. |

Fins have the important task of passive trajectory stabilization. Passive means that there isn't any controlled actuator that can change their attitude. If attitude can't be changed with active systems, then the rocket must be aerodynamically stable. In other words: if a perturbating force or moment acts on the rocket and deviates it from the initial orientation, then the rocket has to aim back to its original heading. It works like a mass-spring-damper system.

The first step is to find an efficient foil that is suitable for a rocket fin. It's wrong to think thinner equals better. Why? Because if you want to make your rocket stable you have to generate a lift force that balances a deviation moment. Lift is given by 1/2rho*V^2*CL*S where CL is the lift coefficient and S is the fin surface. If you consider a thin foil it will stall before a thicker one. So, to avoid stall, you need more surface! What does it mean? That increasing surface you increase drag: D=1/2rho*V^2*CD*S. Increasing drag reduces the apogee; or, from another point of view, makes your motor bigger (and heavier) to reach the same altitude. The most suitable foil is the one which carries the lower CD*S. It has been estimated that a maximum 10N lateral force can be generated by the rocket motor during combustion.

This is the perturbation value considered while designing the passive stabilization.

Structure

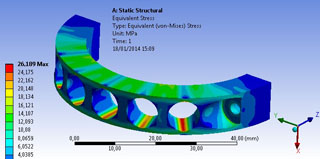

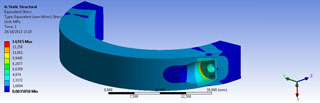

Retaining ring FEM 1. |

Retaining ring FEM 1. |