|

|

This is the first attempt to design, build and test a solid rocket motor with a spike nozzle.

There are several reasons that can justify the use of a spike nozzle instead of the traditional C/D nozzle; however these reasons are convenient for a long duration ignition.

So we tested the actual feasibility of this kind of rocket motor with its advantagese and disadvantages. The PSM 1 was a low pressure attempt with only 3 of 4 grains to test the whole structure with reduced stresses.

We saw a great erosion in the throat zone and some difficulties with the correct alignment of the spike. Moreover the case (AISI 304 stainless steel), again in the throat region, was heavily thermically stressed; it must be protected with a thermal insulator. Defects of that prototype will be corrected in the future.

|

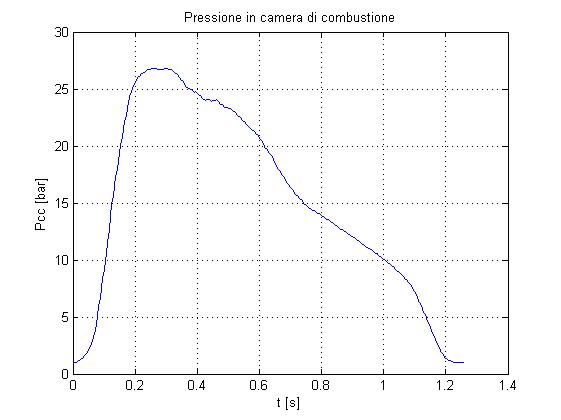

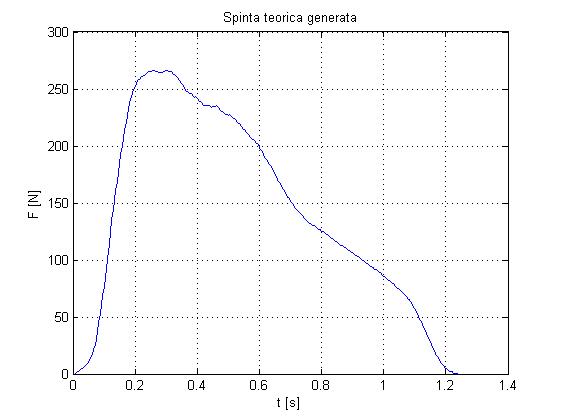

Acquisition frequency [Hz]: 240

Load cell offset [N]: /

0 voltage Red PS [V]: 2.0862

0 voltage Green PS [V]: /

Propellant: P-1

Propellant mass [g]: 208.7

Mean density [g/cm^3]: 1.808

Ideal density ratio: 92.4 %

Grain number: 3

Spacing (between grains) [mm]: 5

Total grain length (without spacing) [mm]: 180.4

Port grain diameter [mm]: 17.1

External grain diameter [mm]: 33.30

Equivalent Throat diameter [mm]: 9.24

Inhibition: External, final terminated (grain interfaces not-inhibited).

Action time (ta) [s]: 1.237

Burn time (tb)[s]: =ta

Maximum thrust [N]: 266.2

Mean thrust (tb)[N]: 142.4

Mean pressure (tb)[bar]: 15.2

Total impulse [Ns]: 179.2

Specific impulse [s]: 87.5

Pyrogen:

Propellant: P-1

Grain mass [g]: 5.37

Grain length [mm]: 15.9

Port Diameter [mm]: 12.1

External Diameter [mm]: 20.4

Environmental data:

Atmospheric pressure [mbar]: na

Air temperature [°C]: na

|

|

|