|

|

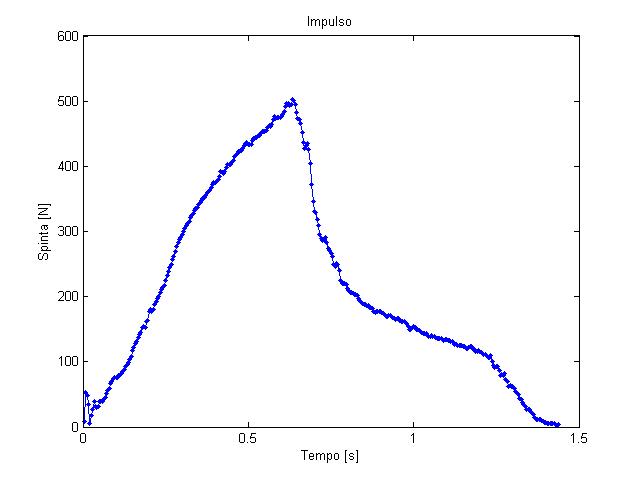

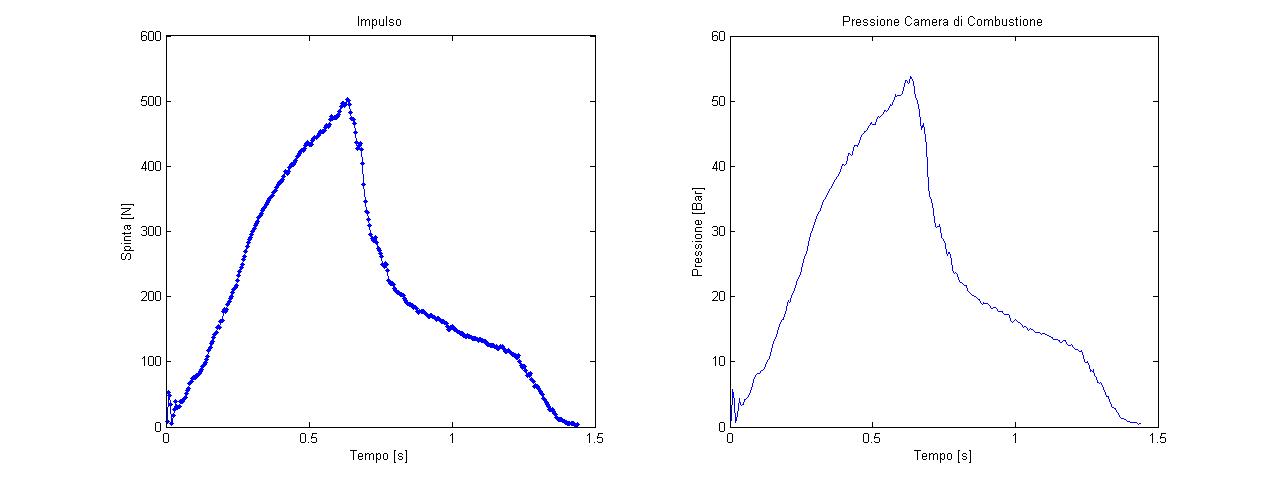

The main innovation of this test has been the use of a De Laval nozzle. Every other aspect(number of grains,inhibitions..) was kept identical to PDM2: the aim was to maintain a thrust curve similarl to PDM2.

The reason of the experiment's non-repeatability is to blame on unexpected factors such as burning chamber depressurization due to o-ring failure, and grain alteration caused by prolonged storage.

In the following test we will try to solve those issues.

|

Acquisition frequency [Hz]: 240

Propellant: P-1

Propellant Mass [g]: 261.8

Mean density [g/cm^3]: 1.846

Ideal density ratio: 97.8 %

Grain number: 3

Total grain length [mm]: 202

Port grain diameter [mm]: 8

Throat diameter [mm]: 8.5

Inhibition: External, final terminated (intergrain faces not inhibited).

Action time (ta) [s]: 1.242

Burn time (tb)[s]: 1.130

Maximum thrust [N]: 502.4

Mean thrust (tb)[N]: 213.3

Mean pressure (tb)[bar]: 27.6

Total impulse [Ns]: 305

Specific impulse [s]: 119.4

Environmental data:

Atmospheric pressure [mbar]: 1031

Air temperature [°C]: 12

|

|

|