|

|

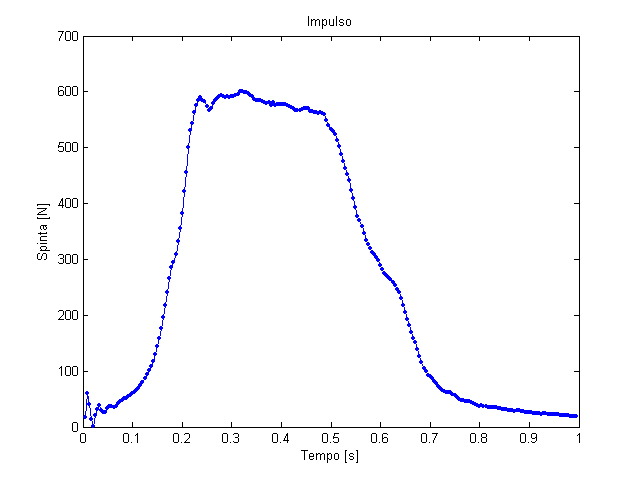

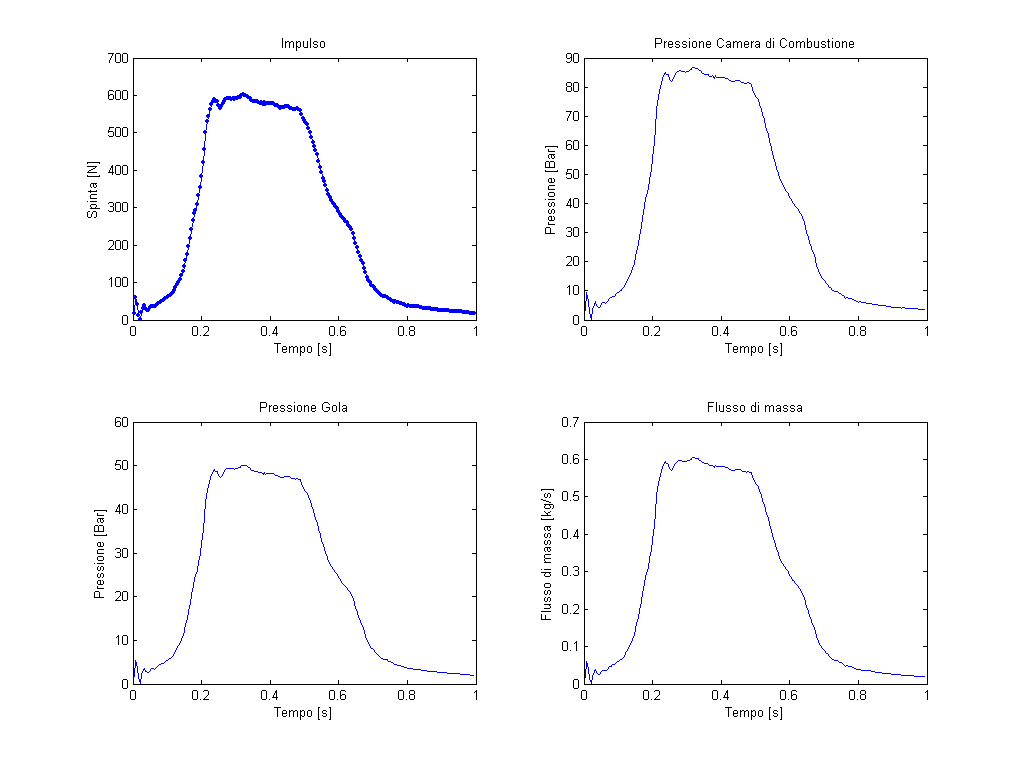

This test sought to stabilize the thrust curve acting on the grain geometry and an augmented powder volume in the igniter. We had used a three grains configuration, whose four internal surfaces were not-inhibited (as opposed to earlier configurations); the two ends were kept inhibited (final terminated).

Every goal has been met. We need to focus more on ignition and end phases. The combustion area kept itself almost constant, showing an almost neutral trend.

The goal now was to adopt a converging-diverging nozzle to optimize the specific impulse, which was in the low range.

|

Acquisition frequency [Hz]: 240

Propellant: P-1

Propellant Mass [g]: 265.2

Mean density [g/cm^3]: 1.852

Ideal density ratio: 98.1%

Grain number: 3

Total grain length [mm]: 203.3

Port grain diameter [mm]: 8

Throat diameter [mm]: 8.5

Inhibition: External, final terminated (intergrain faces not inhibited).

Action time (ta) [s]: 0.637

Burn time (tb)[s]: 0.383

Maximum thrust [N]: 601.3

Mean thrust (tb)[N]: 474.2

Mean pressure (tb)[bar]: 68.3

Total impulse [Ns]: 263.3

Specific impulse [s]: 101.22

Environmental data:

Atmospheric pressure [mbar]: 1019

Air temperature [°C]: 19

|

|

|